Alpha-Amyl Cinnamic Aldehyde (Jasmonal A) Technical Ingredient Overview

🏭 Manufacturer — IFF

🔎 Chemical Name — 2-Benzylideneheptanal; (E)-2-Pentyl-3-phenylprop-2-enal

🧪 Synonyms — α-Amylcinnamaldehyde, Amyl cinnamal, Jasminal, α-Pentylcinnamaldehyde, α-Amyl-β-phenylacrolein, 2-(Phenylmethylene)heptanal, Flomine, Jasminaldehyde

📂 CAS Number — 122-40-7

📘 FEMA Number — 2061

📘 EC Number — 204-541-5

⚖️ Molecular Weight — 202.29 g/mol

🧬 Molecular Formula — C₁₄H₁₈O

📝 Odor Type — Floral-jasmine

📈 Odor Strength — Moderate to strong (highly diffusive)

👃🏼 Odor Profile — Sweet, floral, jasmine-like with tropical, fruity facets; mild oily-herbaceous undertones; green, powdery notes; waxy and slightly spicy nuances when concentrated

⚗️ Uses — Fine fragrance (jasmine accords, white florals), functional perfumery (soaps, detergents, shampoos), flavor applications (fruit and spice notes)

🧴 Appearance — Pale yellow to light yellow clear liquid

What is Alpha-Amyl Cinnamic Aldehyde?

Alpha-Amyl Cinnamic Aldehyde, commonly known as Jasmonal A or Amyl cinnamal, is a synthetic aromatic aldehyde belonging to the cinnamaldehyde family of fragrance materials. Chemically classified as an α,β-unsaturated aldehyde with a conjugated carbon-carbon double bond system, this ingredient possesses the molecular structure C₁₄H₁₈O with a pentyl (five-carbon) substituent at the alpha position relative to the phenyl ring (Arctander, 1960).

As a member of the cinnamaldehyde derivatives class, it exhibits characteristic structural features including the phenylpropene backbone with an aldehyde functional group. The molecule exists as a mixture of cis and trans stereoisomers, though the trans (E-) isomer predominates in commercial preparations and possesses superior olfactory properties (Bauer, Garbe, & Surburg, 2001).

This material has been identified as a naturally occurring aroma volatile in black tea, though commercial production is exclusively synthetic due to economic and consistency considerations (Sell, 2006).

Historical Background

Alpha-Amyl Cinnamic Aldehyde was discovered in 1947 by Von Baeyer, marking a significant milestone in the fragrance industry's systematic effort to develop cost-effective synthetic alternatives to expensive natural absolutes, particularly jasmine absolute (Pybus & Sell, 1999). This discovery occurred during a transformative period in perfumery when the industry actively sought stable and affordable materials to reproduce the complex profiles of luxury natural absolutes such as jasmine, rose, and orange blossom.

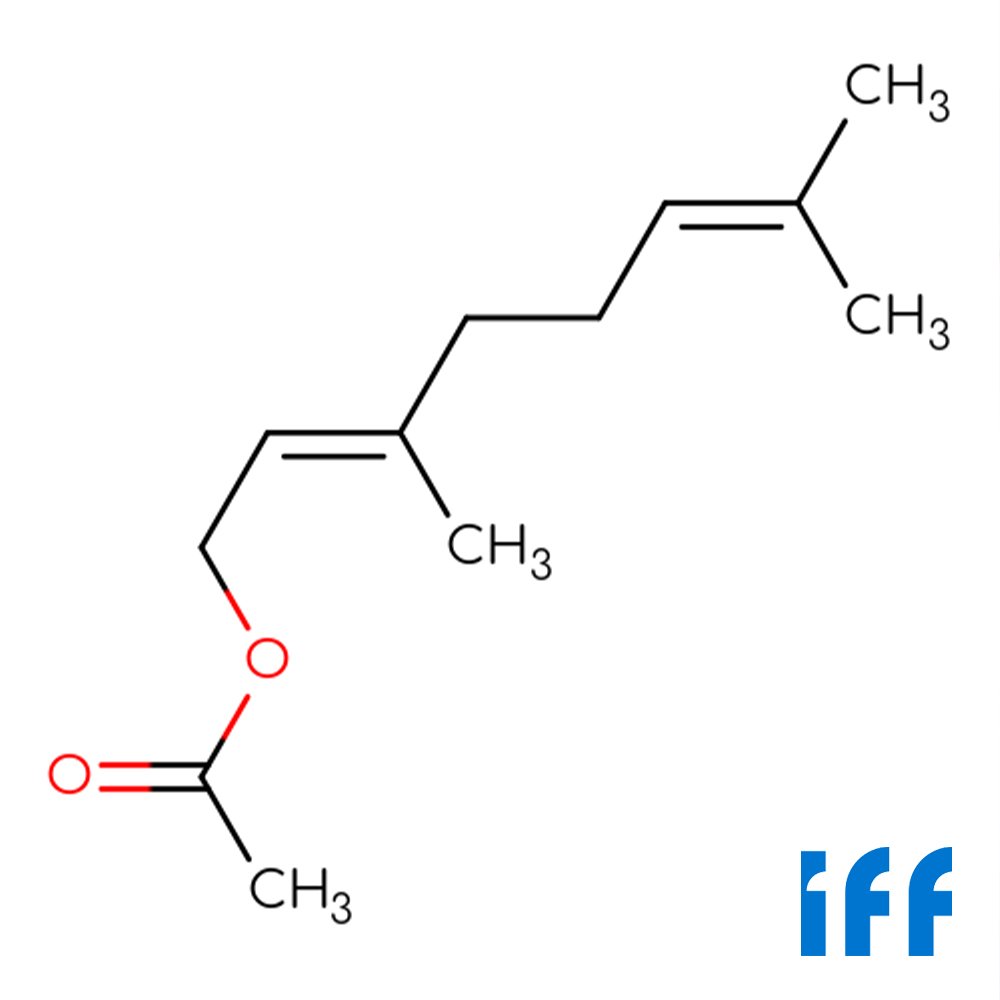

The development of α-amylcinnamaldehyde occurred during a transformative period when perfumery transitioned from reliance on natural materials toward synthetic-floral innovation. Rather than replicating jasmine's heady indolic character, Jasmonal A contributed warm, sweet, and diffusive floral tones with creamy, ambery facets—complementing other jasmine reconstructions such as benzyl acetate, methyl anthranilate, and cis-jasmone (Pybus & Sell, 1999).

Its synthesis methodology—aldol condensation of benzaldehyde with heptanal—became a classical example of carbonyl chemistry applied to fragrance creation, establishing a template for subsequent aromatic aldehyde development.

Olfactory Profile

Scent Family

Primary Classification: Floral-Jasmine

Secondary Classification: White Floral, Oriental-Floral

Chemical Class: Aromatic Aldehyde, Cinnamaldehyde derivative

Main Descriptors

Alpha-Amyl Cinnamic Aldehyde presents a complex olfactory profile characterized by:

Floral Character: Soft jasmine-like floralcy with gardenia and tuberose undertones

Sweet-Fruity Facets: Tropical fruit nuances (peach, apricot) with waxy-peachy accents

Herbaceous-Green Notes: Mild oily-herbaceous quality providing natural freshness

Spicy-Cinnamic Accent: Subtle spice note from cinnamaldehyde structure

Powdery-Balsamic Base: Warm, slightly ambery, creamy drydown

When diluted, the floral-jasmine character becomes more refined and elegant, while concentrated samples reveal more pronounced fatty, waxy aspects (Arctander, 1969).

Intensity

Odor Strength: Moderate to strong. Alpha-Amyl Cinnamic Aldehyde exhibits high diffusivity and substantivity. When smelling a fresh sample directly, the perceived odor may seem relatively weak; however, when the material is left in a room, its delicate floral scent fills the entire space—demonstrating exceptional volatility and projection (Bauer et al., 2001).

Tenacity

Longevity: Excellent persistence (256+ hours on blotter strips). The material demonstrates remarkable staying power on both textiles and skin, maintaining its floral character throughout extended evaporation periods. This exceptional tenacity contributed significantly to its widespread adoption in functional perfumery applications.

Volatility

Evaporation Rate: Medium to slow

Classification: Middle to base note

Boiling Point: 287-290°C

Vapor Pressure: 0.133 Pa at 25°C (extremely low, indicating slow evaporation)

The relatively high boiling point and low vapor pressure classify this material as a middle-to-base note component, providing lasting floral impact in fragrance compositions.

Fixative Role

Alpha-Amyl Cinnamic Aldehyde functions as a soft fixative, assisting in the retention and blending of more volatile top note components. Its ability to enhance and prolong the perception of accompanying floral materials makes it particularly valuable in jasmine, gardenia, and white floral accords. The material demonstrates excellent blending properties and assists in the overall fixation of fragrance compositions (Arctander, 1969).

Applications in Fine Fragrance

Alpha-Amyl Cinnamic Aldehyde plays a significant role in various fragrance compositions:

Primary Applications:

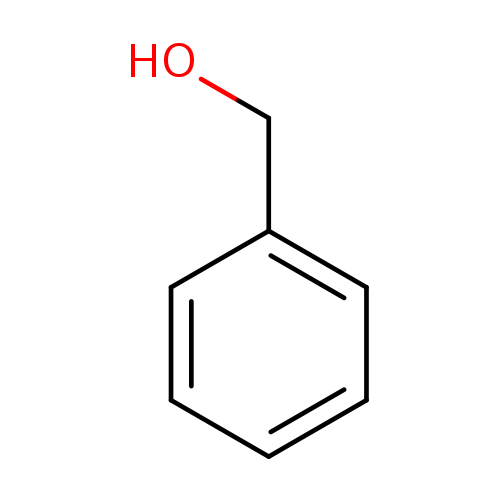

Jasmine Reconstructions: Essential component in synthetic jasmine accords, often used alongside benzyl acetate, linalool, indole, and methyl anthranilate

White Floral Bouquets: Gardenia, tuberose, orange blossom, magnolia compositions

Oriental Florals: Provides warm, sweet floral base in ambery-floral fragrances

Fruity Florals: Enhances peach, apricot, and tropical fruit aspects in modern floral compositions

Typical Accords:

Works synergistically with indolic materials (indole, methyl anthranilate) to create fuller jasmine notes

Pairs effectively with benzyl acetate and benzyl alcohol for soft, creamy florals

Complements ylang-ylang, tuberose absolutes, and neroli for complex white floral effects

Enhances citrus top notes with soft floral warmth

Usage Levels: Typical use concentrations range from 0.5% to 7% in finished fragrances, depending on desired intensity and regulatory compliance (IFRA restrictions apply).

Performance in Formula

Blending Behavior: Alpha-Amyl Cinnamic Aldehyde exhibits excellent compatibility with most fragrance materials. Its mild character and balanced volatility allow smooth integration into complex compositions without dominating or clashing with other components.

Impact on Composition:

Rounding Effect: Softens and harmonizes sharp or angular notes

Volume Enhancement: Increases the perceived fullness and body of floral accords

Diffusion: Improves the projection and sillage of fragrances

Naturalness: Contributes to a more authentic, less synthetic floral impression

Stability Considerations: The aldehyde functionality renders this material relatively unstable and prone to oxidation. Stabilization with antioxidants (e.g., BHT, BHA) is necessary to prevent degradation during storage. The material is stable to alkali, making it suitable for soap perfumery applications (Bauer et al., 2001).

Industrial & Technical Uses

Beyond fine fragrance, Alpha-Amyl Cinnamic Aldehyde finds extensive application in:

Functional Perfumery:

Laundry detergents and fabric softeners

Shampoos and hair care products

Body washes and liquid soaps

Surface cleaners and household products

Air fresheners and deodorizers

Due to its alkali stability, high substantivity, and low cost relative to natural jasmine, this material became a staple in functional applications where jasmine-floral character is desired (Pybus & Sell, 1999).

Flavor Applications: FEMA GRAS status (FEMA #2061) permits use as a flavoring agent. At approximately 40 ppm, it provides sweet, floral, spice-like notes with cinnamic and waxy nuances. Applications include:

Fruit flavor systems (peach, apricot, cherry, strawberry)

Spice and cinnamon flavor profiles

Nut flavors (almond, walnut)

Confectionery and beverage applications

Regulatory & Safety Overview

IFRA Status

Restriction Level: Alpha-Amyl Cinnamic Aldehyde is restricted under IFRA standards.

Current Amendment: Amendment 51 (2023) maintains restrictions established in Amendment 49 (2020)

Product Category Limitations: Maximum acceptable concentrations vary by product category based on dermal sensitization and systemic toxicity endpoints

Category 4 Restriction: Limited to 7.0% maximum concentration in hydroalcoholic products applied to recently shaved skin (Amendment 49)

Official IFRA Standard: Available at https://ifrafragrance.org/standards/

The IFRA restrictions are based on Research Institute for Fragrance Materials (RIFM) safety assessments conducted by the Expert Panel for Fragrance Safety.

EU Cosmetics Regulation

Declarable Allergen Status: Alpha-Amyl Cinnamic Aldehyde (INCI: Amyl Cinnamal) is one of the 26 regulated fragrance allergens listed in Annex III of EU Regulation 1223/2009.

Labeling Requirements:

Must be declared on product labels when present at ≥0.001% in leave-on products

Must be declared on product labels when present at ≥0.01% in rinse-off products

Identified as a well-recognized consumer allergen (List A in SCCNFP Opinion 1999)

This regulatory status reflects clinical evidence of contact sensitization potential in susceptible individuals.

FEMA Status

GRAS Classification: Generally Recognized As Safe (GRAS) for use as a flavoring agent

FEMA Number: 2061

JECFA Number: 685

CFR Reference: 21CFR172.515

The FEMA Expert Panel reviewed cinnamyl derivatives and concluded that α-amylcinnamaldehyde is safe for use in food flavoring at current use levels (Adams et al., 2004).

Toxicology

Safety Profile: Moderately toxic by ingestion in animal studies. The material has been evaluated in short-term feeding studies in rats without significant adverse findings at typical exposure levels (Adams et al., 2004).

Primary Concern: Skin sensitization potential. Alpha-Amyl Cinnamic Aldehyde is an oxidation product of α-amylcinnamic alcohol, a component of the "fragrance mix" used in dermatological patch testing. It has been identified as a sensitizer in cases of occupational contact dermatitis, including among bakers and perfumery workers.

Safety Recommendations:

Use within IFRA concentration limits

Employ appropriate stabilization to prevent oxidative degradation

Avoid use on damaged or inflamed skin

Implement good manufacturing practices to minimize sensitization risk

GHS Classification (Globally Harmonized System):

H317: May cause an allergic skin reaction (Skin Sensitization, Category 1)

H411: Toxic to aquatic life with long lasting effects (Aquatic Chronic, Category 2)

Synthesis & Production

Alpha-Amyl Cinnamic Aldehyde is synthesized via aldol condensation of benzaldehyde with n-heptanal (heptaldehyde), a classical organic reaction that forms α,β-unsaturated aldehydes.

Reaction Mechanism: The synthesis proceeds through base-catalyzed aldol condensation followed by dehydration:

Heptanal is converted to its enolate anion under basic conditions

The enolate performs nucleophilic attack on the carbonyl carbon of benzaldehyde

The resulting β-hydroxyaldehyde intermediate undergoes dehydration

Formation of the conjugated α,β-unsaturated aldehyde (jasminaldehyde)

Industrial Catalysts: Modern industrial production utilizes heterogeneous base catalysts such as:

Mg-Al mixed oxides (hydrotalcites)

Calcined layered double hydroxides (LDHs)

Modified mesoporous silicas

These solid base catalysts offer advantages including reusability, reduced waste generation, and elimination of liquid alkali disposal issues. Optimal synthesis conditions typically involve heptanal:benzaldehyde ratios of 1:2 to 1:5, temperatures of 80-150°C, and may employ solvent-free conditions to improve atom economy (Sharma, Parikh, & Jasra, 2008; Yadav & Aduri, 2012).

Selectivity Challenge: The synthesis must balance the desired cross-aldol condensation (benzaldehyde + heptanal) against undesired self-condensation of heptanal, which produces 2-pentylnon-2-enal as a byproduct. Catalyst design and reaction engineering focus on maximizing selectivity toward jasminaldehyde (typically 60-86% selectivity achievable).

Physical & Chemical Properties

Appearance: Pale yellow to light yellow clear liquid

Density: 0.963-0.969 g/mL at 25°C (lit. 0.97 g/mL)

Refractive Index: n₂₀/D = 1.554-1.559 (lit. 1.557)

Boiling Point: 287-290°C

Flash Point: >110°C (closed cup); reported values 94-146°C

Melting Point: <0°C

Solubility:

Insoluble in water

Soluble in alcohol and most organic solvents

Soluble in fixed oils and mineral oil

Insoluble in glycerin and propylene glycol

Storage: Store at 2-8°C in tightly closed containers, protected from light and air oxidation

Quality Control & Specifications

Typical Commercial Specifications:

Purity: ≥90-97% (GC)

Appearance: Pale yellow to yellow clear liquid

Odor: Characteristic sweet, floral, jasmine-like

Density: 0.963-0.969 g/cm³ at 25°C

Refractive Index: 1.554-1.559 at 20°C

Acid Value: ≤1.0 mg KOH/g

Impurities & Side Products: Commercial material may contain traces of:

Starting materials (benzaldehyde, heptanal)

Self-condensation byproduct (2-pentylnon-2-enal)

Cis-isomer (minor stereoisomer)

Oxidation products (if improperly stored)

References

Adams, T. B., Cohen, S. M., Doull, J., Feron, V. J., Goodman, J. I., Marnett, L. J., Munro, I. C., Portoghese, P. S., Smith, R. L., Waddell, W. J., & Wagner, B. M. (2004). The FEMA GRAS assessment of cinnamyl derivatives used as flavor ingredients. Food and Chemical Toxicology, 42(2), 157-185.

Arctander, S. (1960). Perfume and flavor materials of natural origin. Elizabeth, NJ: Self-published.

Arctander, S. (1969). Perfume and flavor chemicals (aroma chemicals). Carol Stream, IL: Allured Publishing.

Bauer, K., Garbe, D., & Surburg, H. (2001). Common fragrance and flavor materials: Preparation, properties and uses(4th ed.). Weinheim: Wiley-VCH.

European Commission. (2009). Regulation (EC) No 1223/2009 of the European Parliament and of the Council on cosmetic products. Official Journal of the European Union, L 342/59.

IFRA (International Fragrance Association). (2020). IFRA Standard: alpha-Amyl cinnamic aldehyde (Amendment 49). Retrieved from https://ifrafragrance.org/standards/IFRA_STD_005.pdf

IFRA (International Fragrance Association). (2023). Index of IFRA Standards - 51st Amendment. Retrieved from https://ifrafragrance.org/

Pybus, D. H., & Sell, C. S. (Eds.). (1999). The chemistry of fragrances. Cambridge: Royal Society of Chemistry.

SCCNFP (Scientific Committee on Cosmetic Products and Non-Food Products). (1999). Opinion concerning fragrance allergy in consumers (SCCNFP/0017/98). Brussels: European Commission.

Sell, C. S. (2006). The chemistry of fragrances: From perfumer to consumer (2nd ed.). Cambridge: Royal Society of Chemistry.

Sharma, S. K., Parikh, P. A., & Jasra, R. V. (2008). Eco-friendly synthesis of jasminaldehyde by condensation of 1-heptanal with benzaldehyde using hydrotalcite as a solid base catalyst. Journal of Molecular Catalysis A: Chemical, 286(1-2), 55-62.

Yadav, G. D., & Aduri, P. (2012). Aldol condensation of benzaldehyde with heptanal to jasminaldehyde over novel Mg-Al mixed oxide on hexagonal mesoporous silica. Journal of Molecular Catalysis A: Chemical, 355, 142-154.